1.1 HVAC SYSTEM

Air conditioning study is one of the most complicated studies and is done in various stages. Heat load calculation takes into account the heat developed due to occupancies as well as the equipment present inside, and also the environmental factors affecting the same. During heating installation, only the heat load calculation has to be performed. But when it comes to HVAC, heat load calculation is accompanied by cooling load calculation, sharing equal importance required for designing the system.

An engineer thus has to have perfect knowledge of the construction, the surrounding environment, occupancies, etc., concerning the system before actually installing the AC system. The next step will be the selection of appropriate equipment according to the observations obtained through the above analysis. By selecting the proper size and load-taking capacity equipment, the main motto of comfort, along with energy saving, will be attained. If we select an air conditioning system of a larger size than the required size, then it will lead to high initial as well as high running cost. On the contrary, if the air conditioning system of a smaller size is fitted than the required size, then there will be undercooling and the very purpose of the installation of a system will not be accomplished.

The aim of this paper is to develop or explain the steps required for designing an AC system with proper heat load calculations. The HVAC designer specifies the size of the system which gives maximum efficiency at the lowest running cost. This aim of this paper is accomplished in a few stages. Each stage is explained in detail further. Today, A/C equipment represents close to a $100 billion, 100 million-unit per year global market, and accounts for 4.5 exa-joules (4.26 Quadrillion Btu) of site energy consumption per year, comprising just over 4% of global building site-energy consumption. While adoption of A/C in developed countries increased rapidly in the 20th century, the 21st century will see greater adoption in developing countries, especially those in hot and (possibly) humid climates with large and growing populations, such as India, China, Brazil, and Middle Eastern nations.

The International Energy Agency (IEA) projects that A/C energy consumption by 2050 will increase 4.5 times over 2010 levels for non-Organization of Economic Coordination and Development (OECD) countries versus 1.3 times for OECD countries. Rising income and greater access to A/C equipment in many of these nations opens the door to building cooling for billions of people, which will provide significant benefits in increased human health and comfort. Therefore, we move towards designing an HVAC system for minimizing energy utilization and energy conservation. Heating, Ventilation, and Air-Conditioning system is an indoor system designed by WILLIAM HAVILLAND CARRIER in 1902 at Sackett-Wilhelms Lithographing and Publishing Company in Brooklyn, New York. An air-conditioning system provides cooling and humidity control for all the parts of the system. An air-conditioned system is air-sealed in order to maintain constant environmental conditions. Ventilation plays an important role when it comes to the AC system. It is the process of replacing or exchanging air within the system in order to provide high air quality and removal of odours, smoke, heat, and dust that gets accumulated in the system with time.

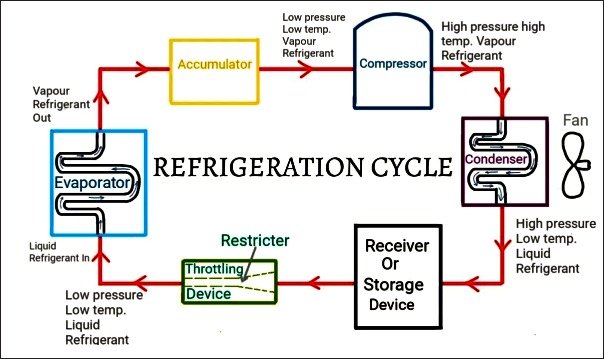

1.2 BASIC REFRIGERATION CYCLE

The basic refrigeration cycle consists of condenser, compressor, evaporator, and expansion valve. A compressor is a mechanical device that increases the pressure of gas at the expense of the volume of gas. These are similar to pumps as both can transport fluids through pipes. Basically, a condenser is a device which condenses a substance from its gaseous state to its liquid state by cooling it. It works on the principle of transfer of latent heat to the surroundings, leading to a change in state.

Figure 1.2.1 – Refrigeration Cycle

An evaporator is a device used to evaporate the liquid form of a substance into its gaseous form. An expansion valve is one of the most important components of the refrigeration cycle as it controls the amount of refrigerant flowing into the system.

3.1 PROBLEM DEFINITION

The average summer temperatures experienced by most countries are increasing every year, and consequently, the energy needed to provide air-conditioning is also increasing annually. The HVAC industry has a challenging task of providing energy-efficient technologies to satisfy this growing demand with a minimum impact on global warming and ozone depletion. The chilled water types of central air conditioning plants are installed in places where whole large buildings, shopping malls, airports, hotels, etc., comprising several floors, are to be air-conditioned.

The project consists of how the proposed centralized air conditioning is designed and its criterion for a new building in Hyderabad. It consists of 6 floors having an area of 4,000 sqft. per floor. The main objective is to create a thermally controlled environment within the space of a building envelope such as kitchen room, master bedroom, dining room, etc. The tentative air conditioning load for the system shall be 290 TR approx. Air-cooled chillers with pumping systems are proposed to make the system energy efficient. The proposed air conditioning plant shall be located on the building terrace.

Keywords: Humidification, Dehumidification, Infiltration, Ventilation, Dry Bulb Temperature, Wet Bulb Temperature, Dew Point Temperature, Relative Humidity, Specific Humidity, Indoor-Air-Quality, British Thermal Unit, Ton of Refrigeration.

THE VARIOUS MODULES USED AND THEIR FUNCTIONALITIES ARE DISCUSSED AS FOLLOWS:

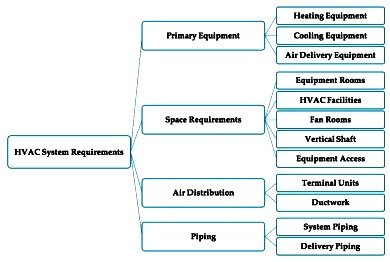

Four requirements are the bases for any HVAC systems [4]. They need primary equipment, space requirement, air distribution, and piping, as shown in Figure.

Figure: 3.1.1 HVAC System Requirement

Primary equipment includes heating equipment such as steam boilers and hot water boilers to heat buildings or spaces, air delivery equipment as packaged equipment to deliver conditioned ventilation air by using centrifugal fans, axial fans, and plug or plenum fans, and refrigeration equipment that delivers cooled or conditioned air into space. It includes cooling coils based on water from water chillers or refrigerants from a refrigeration process.

Space requirement is essential in shaping an HVAC system to be central or local. It requires five facilities as the following:

1. Equipment rooms: since the total mechanical and electrical space requirements range between 4 and 9% of the gross building area. It is preferable to be centrally located in the building to reduce the long duct, pipe, and conduit runs and sizes, to simplify shaft layouts, and to centralize maintenance and operation.

2. HVAC facilities: heating equipment and refrigeration equipment require many facilities to perform their primary tasks of heating and cooling the building. The heating equipment requires boiler units, pumps, heat exchangers, pressure-reducing equipment, control air compressors, and miscellaneous equipment, while the refrigeration equipment requires water chillers or cooling water towers for large buildings, condenser water pumps, heat exchangers, air-conditioning equipment, control air compressors, and miscellaneous equipment. The design of equipment rooms to host both pieces of equipment should consider the size and the weight of equipment, the installation and maintenance of equipment, and the applicable regulations to combustion air and ventilation air criteria.

3. Fan rooms contain the HVAC fan equipment and other miscellaneous equipment. The rooms should consider the size for the installation and removal of fan shafts and coils, the replacement, and maintenance. The size of fans depends on the required airflow rate to condition the building, and it can be centralized or localized based on the availability, location, and cost. It is preferable to have easy access to outdoor air.

4. Vertical shaft: provides space for air distribution and water and steam pipe distribution. The air distribution contains HVAC supply air, exhaust air, and return air ductwork. Pipe distribution includes hot water, chilled water, condenser water, and steam supply, and condenser return. The vertical shaft includes other mechanical and electrical distribution to serve the entire building, including plumbing pipes, fire protection pipes, and electric conduits/closets.

5. Equipment access: the equipment room must allow the movement of large, heavy equipment during installation, replacement, and maintenance.