According to a biomedical point of view, biocompatibility is the capacity of a material to perform with a suitable host reaction in a particular application.

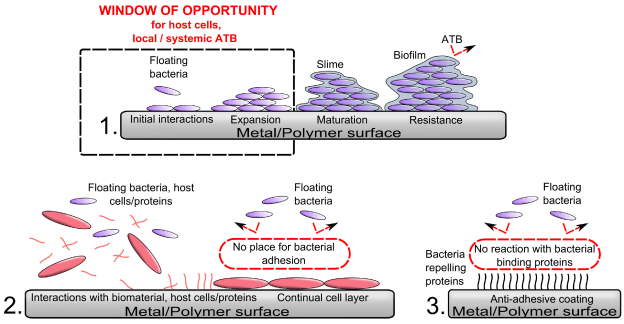

It is portrayed to be non-poisonous, no instigated unfavorable responses, for example, constant fiery reaction with unordinary tissue arrangement, and intended to work appropriately for a sensible lifetime. It is a prerequisite of biomaterials in which the surface altered material will make no mischief the host, and the material itself won’t hurt by the host. Modification of surface should be possible through different techniques, which can be ordered through three primary gatherings: (physical adsorption, Langmuir Blodgett film), compound (oxidation by solid acids, ozone treatment, chemisorption, and fire treatment) and radiation (shine release, crown release, photograph enactment (UV), laser, particle pillar, plasma submersion particle implantation, electron shaft lithography, and γ-illumination). It includes the essentials of physicochemical collaborations between the biomaterial and the physiological condition at the atomic, cell, and tissue levels (decrease bacterial grip, advance cell bond). Right now, there are different techniques for portrayal and surface alteration of biomaterials and valuable uses of central ideas in a few biomedical arrangements. Proteins are comprised of various groupings of amino acids, proteins can have different capacities as its auxiliary shape driven by various sub-atomic bonds can change. Amino acids display various qualities, for example, being polar, non-polar, decidedly, or adversely charged which is dictated by having distinctive side chains. In this manner, the connection of particles with various proteins, for instance, those containing Arginine-Glycine-Aspartate (RGD) arrangements are relied upon to adjust the outside of tissue platforms and result in progress of cell attachment when set into its physiological condition.

A portion of the modification of surface procedures recorded above is especially utilized for specific capacities or sorts of materials. One of the benefits of plasma drenching particle implantation is its capacity to treat most materials. Particle implantation is a successful surface treatment method that is utilized to upgrade the surface properties of biomaterials. The novel preferred position of plasma change is that the surface properties and biocompatibility can be improved specifically while the ideal mass qualities of the materials, for example, quality stay unaltered. Plasma procedures are particularly valuable since they can store ultra meager (a couple of nm), disciple, conformal coatings. Sparkle release plasma is made by filling a vacuum with a low-pressure gas (ex. argon, smelling salts, or oxygen). The gas is then energized utilizing microwaves or current which ionizes it. The ionized gas is then tossed onto a surface at a high speed where the vitality delivered truly and artificially changes the surface. Biointegration is a definitive objective in for instance orthopedic inserts that bones build up a precisely strong interface with complete combination between the fake embedded material and bone tissues under great biocompatibility conditions. Adjusting the outside of a material can improve its biocompatibility, and should be possible without changing its mass properties. The properties of the highest sub-atomic layers are basic in biomaterials. The immune system will respond contrastingly if an embed is covered in extra-cell lattice proteins. The proteins encompassing the embed serve to “cover-up” the embed from the intrinsic invulnerable framework. Be that as it may, if the embed is covered in allergenic proteins, the patient’s versatile invulnerable reaction might be started. Physical immobilization is essentially covering material with a biomimetic material without changing the structure of either. Different biomimetic materials with cell glue proteins, (for example, collagen or laminin) have been utilized in vitro to coordinate new tissue development and cell development. Moreover, albeit a portion of the biomaterials has great biocompatibility, it might have poor mechanical or physical properties, for example, wear obstruction, hostile to erosion, or wettability or lubricity. In these cases, surface alteration is used to store a layer of covering or blending in with the substrate to shape a composite layer.

Biomaterial’s surface modification with proteins

on 04/07/2020