Pakistan is passing through a challenging situation, apart from political challenges, economic challenges are very big for the government and people.

During the last few fiscal years, our imports were increasing and exports were decreasing. It is alarming that the industrial base is shirking as reduction of electricity consumption by

industries in the last several years.

Slowly and quietly, we became a consumption society for all the foreign goods from a bar of chocolate to big machines. The local industrial contributions in GDP is being reduced in last many years. The local industries were being closed due to a non-competitive environment. They were unable to compete with imported goods. The effects were, well known. That is unemployment and a serious balance of payment issues. We have to borrow dollars from every corner of the world.

The present government has taken some difficult decisions to recover the bad situation. We have to take more such steps at all level in the government to facilitate the use of indigenous

technology and equipment before it is too late.

All the state organs of the country such s government, bureaucracy, the establishment, and the civil society must support the initiative of “Made in Pakistan”, and take every small and big step to encourage the use of locally made components, products, machines, equipment as well as hiring of local consultant for the projects, etc.

“Made in Pakistan” means all of us should use and encourage locally produce goods. All our policies should be focused on reviving our engineering goods industries to produce locally

manufactured product.

The present government of Pakistan is continuously taking initiative for “ease of doing business” encouraging various sectors of industries for investment, as well as the revival of sick units.

The government has set a big export target for 2025. To achieve the target, our major contributors are the textile sector. These textile sector industries need investment to increase their capacity.

Similarly, there is also discussion that by 2030 the energy mix shall be changed to 30 percent from present less than 1 percent to renewable in particular clean energy (solar and wind).

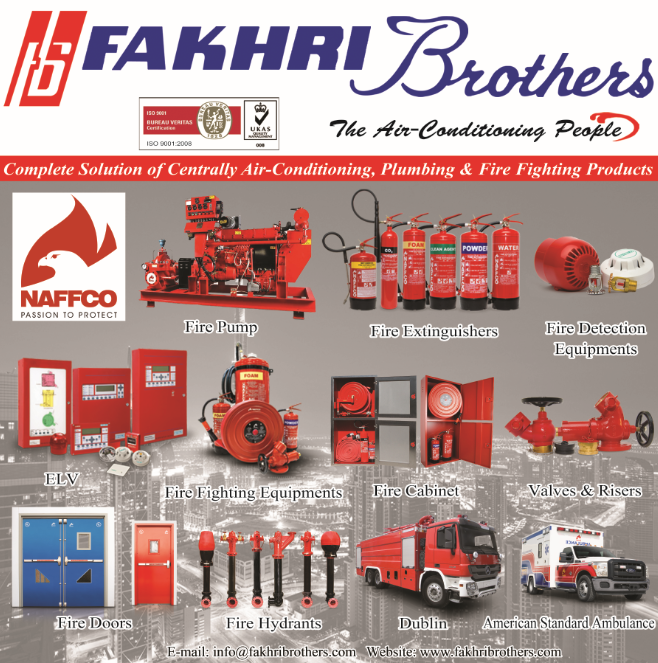

We are using about 1 million air conditioners every year. The quantity may touch 1.3 to 1.5 million in the next 3 to 5 years.

The following are some opportunities to focus on “Made in Pakistan”.

The various component of air conditioners like air-compressors, refrigerator gases, refillable cylinders, copper pipe, and fittings, etc. are being imported which can be manufactured locally.

The local textile and engineering industries should find ways and means to motivate some of the international textile machine manufacturers to start assembly/manufacturing in Pakistan through joint ventures. Initially, these machines can be imported in the SKD condition and later on in CKD condition. This shall save foreign exchange and shall create new job opportunities. The textile sector is the main driver in the export of goods, and a little step shall be a benchmark as well

as a role model for other industries to produce locally made components, equipment, and machines.

The renewable energy sector also needs to focus on Made in Pakistan initiative. The GOP should focus its attention on the local manufactures of renewable energy components like

use of concrete turbine tower, fan blades, and other related balance of plant equipment.

Electrical vehicle and related equipment

• Buses being used in mass transport (Green Line, etc.)

• The Federal and all Provincial governments and arm forces departments must encourage purchasing of Made in Pakistan products and equipment.

The private entrepreneur always took the various initiatives in developing a locally indigenous solution which saves a huge amount of foreign exchange e.g. cleaning and washing of windmill blade during operations.

The universities in Pakistan have to be involved in the economic process to address various economic challenges. The joint venture initiative between private sector industries and

foreign manufacturers industries must be encouraged as a policy guideline which is a very successful model adopted by China and Malaysia. Encouraging the establishment of new

industries as well as revival sick units through joint venture initiative shall help in resolving quality issues, transfer of technology and skill development locally.

Actions suggested

• GOP long term (10 – 15 years) policy emphasizing on local manufacturing

• More initiative for “Ease of Doing Business” from Federal, Provincial and City Governments

• The incentive for new foreign and local investment in engineering goods manufacturing industries established in any part of Pakistan

• More initiative in the reduction of “Cost of Doing Business” (e.g. reduction in utility charges, etc.)

• To provide an enabling environment for the local engineering goods manufacturers & services

Improvement in IR law to meet 21st-century challenges

• Focus on enhancement in productivity at all levels

• Supporting attitude towards local manufacturing by all government organization/department

• Implementing SRO 827 in Public Sector procurement vigorously

• On job training to fresh engineers

• Implementation of apprentice scheme for the development of shop floor skilled manpower

Made in Pakistan

on 03/04/2020